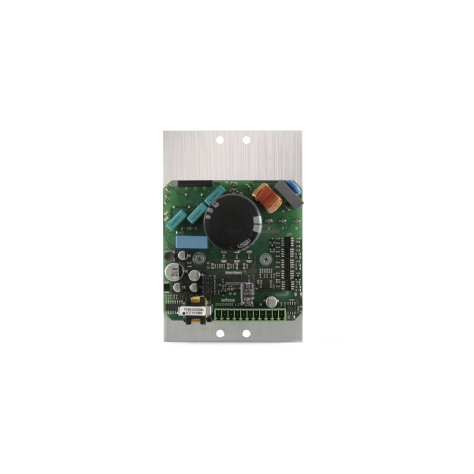

Inverter Slim

Inverter for asynchronous motors with up to 250 W power

The Iinverter Slim is used for optimum control of AC three-phase asynchronous motors, also known as induction motors (IM), as it improves performances and energy efficiency.

Designed for power capacity up to 250 W, it is suitable to operate compact conveyor ovens and small-size fans in the refrigeration and baking industry.

The inverter operates with scalar (V/f) or PID vector control and includes a command for the reverse of rotation direction and various protection functions. It is equipped with an EMC mains filter which lowers medium- and high-frequency electromagnetic disturbances.

The compact dimensions, the open board format and a Slave RS-485 MODBUS port make it an ideal product for Original Equipment Manufacturers, who can have the inverter built into the machine and connect it via serial port to their own control systems. Control can be customized through parameters and can be managed also via analogue and digital input or via FM input.

Designed for power capacity up to 250 W, it is suitable to operate compact conveyor ovens and small-size fans in the refrigeration and baking industry.

The inverter operates with scalar (V/f) or PID vector control and includes a command for the reverse of rotation direction and various protection functions. It is equipped with an EMC mains filter which lowers medium- and high-frequency electromagnetic disturbances.

The compact dimensions, the open board format and a Slave RS-485 MODBUS port make it an ideal product for Original Equipment Manufacturers, who can have the inverter built into the machine and connect it via serial port to their own control systems. Control can be customized through parameters and can be managed also via analogue and digital input or via FM input.

Technical sheet

Advantages & Main Features

Per maggiori informazioni su questa gamma consulta la versione desktop del sito.

Instructions sheet EI250M2S02O0

Instructions sheet EI250M2S02O0