EVJ 500

Temperature/humidity controllers for cabinets, counters and display units

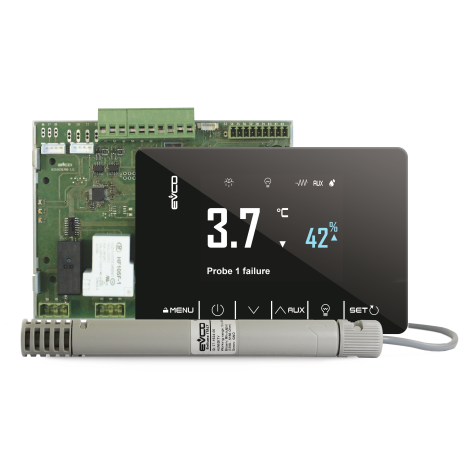

Controllers in the EVJ 500 range are used for all applications requiring temperature and humidity control, such as pastry and praline displays (EVJ506/EVJS506/EVJ526) and for maturing charcuterie and cheese (EVJ536).

These controllers operate with a proprietary probe and have 6 outputs for managing temperature in heating/cooling mode also with a neutral zone, as well as humidity with humidifying/dehumidifying settings using fans and defrosting cycles.

The models for food processing (EVJ536) are capable of running intuitive programmes to optimise the management of stewing, drying and ageing processes. Regulation options include manual or programmed air exchange cycles, as well as a pause-work function. Model 526 can also manage food sanitation and cabinet sterilization cycles (UV lamp and ozone).

The controllers are available with built-in or remote user interface, which has a 2.8 inch colour graphic display, capacitive keys and an IP65 front. It can be fitted to the panel in the conventional way, built into the front, or concealed under the panel (if made of glass or methacrylate), ensuring high cleaning and hygiene standards.

Users can interact remotely with their equipment using the EPoCA® cloud platform with Wi-Fi or Ethernet connectivity (which also enables alternative or parallel control through MODBUS TCP). Onsite, they can interact from a mobile device with the EVconnect® app which uses BLE. For more details, compare all the connectivity options in the Technical Data table and consult the sections of our website: Products/ Management and Monitoring Systems and Products/ Connectivity Devices.

These controllers operate with a proprietary probe and have 6 outputs for managing temperature in heating/cooling mode also with a neutral zone, as well as humidity with humidifying/dehumidifying settings using fans and defrosting cycles.

The models for food processing (EVJ536) are capable of running intuitive programmes to optimise the management of stewing, drying and ageing processes. Regulation options include manual or programmed air exchange cycles, as well as a pause-work function. Model 526 can also manage food sanitation and cabinet sterilization cycles (UV lamp and ozone).

The controllers are available with built-in or remote user interface, which has a 2.8 inch colour graphic display, capacitive keys and an IP65 front. It can be fitted to the panel in the conventional way, built into the front, or concealed under the panel (if made of glass or methacrylate), ensuring high cleaning and hygiene standards.

Users can interact remotely with their equipment using the EPoCA® cloud platform with Wi-Fi or Ethernet connectivity (which also enables alternative or parallel control through MODBUS TCP). Onsite, they can interact from a mobile device with the EVconnect® app which uses BLE. For more details, compare all the connectivity options in the Technical Data table and consult the sections of our website: Products/ Management and Monitoring Systems and Products/ Connectivity Devices.

Technical sheet

-

Instructions sheet EVJ506N2VX3

Instructions sheet EVJ506N2VX3 -

Instructions sheet EVJ526N2EX3

Instructions sheet EVJ526N2EX3 -

Instructions sheet EVJ536N2EX3

Instructions sheet EVJ536N2EX3 -

Instructions sheet EVJ536N2VX3

Instructions sheet EVJ536N2VX3 -

Instructions sheet EVJ536N2VX3XXV

Instructions sheet EVJ536N2VX3XXV -

Instructions sheet EVJS506N9EXXCQ

Instructions sheet EVJS506N9EXXCQ -

Installer manual EVJ506N2VX3

Installer manual EVJ506N2VX3 -

Installer manual EVJ526N2EX3

Installer manual EVJ526N2EX3 -

Installer manual EVJ536N2EX3

Installer manual EVJ536N2EX3 -

Installer manual EVJ536N2VX3

Installer manual EVJ536N2VX3 -

Installer manual EVJ536N2VX3XXV

Installer manual EVJ536N2VX3XXV -

Installer manual EVJS506N9EXXCQ

Installer manual EVJS506N9EXXCQ -

Instructions sheet EVJ506N2VX3

Instructions sheet EVJ506N2VX3 -

Instructions sheet EVJ526N2EX3

Instructions sheet EVJ526N2EX3 -

Instructions sheet EVJ536N2EX3

Instructions sheet EVJ536N2EX3 -

Instructions sheet EVJ536N2VX3

Instructions sheet EVJ536N2VX3 -

Instructions sheet EVJ536N2VX3XXV

Instructions sheet EVJ536N2VX3XXV -

Instructions sheet EVJS506N9EXXCQ

Instructions sheet EVJS506N9EXXCQ -

Installer manual EVJ506N2VX3

Installer manual EVJ506N2VX3 -

Installer manual EVJ526N2EX3

Installer manual EVJ526N2EX3 -

Installer manual EVJ536N2EX3

Installer manual EVJ536N2EX3 -

Installer manual EVJ536N2VX3

Installer manual EVJ536N2VX3 -

Installer manual EVJ536N2VX3XXV

Installer manual EVJ536N2VX3XXV -

Installer manual EVJS506N9EXXCQ

Installer manual EVJS506N9EXXCQ -

Instructions sheet EVJ506N2VX3

Instructions sheet EVJ506N2VX3 -

Instructions sheet EVJ526N2EX3

Instructions sheet EVJ526N2EX3 -

Instructions sheet EVJ536N2EX3

Instructions sheet EVJ536N2EX3 -

Instructions sheet EVJ536N2VX3

Instructions sheet EVJ536N2VX3 -

Instructions sheet EVJ536N2VX3XXV

Instructions sheet EVJ536N2VX3XXV -

Instructions sheet EVJ506N2VX3

Instructions sheet EVJ506N2VX3 -

Instructions sheet EVJ526N2EX3

Instructions sheet EVJ526N2EX3 -

Instructions sheet EVJ536N2EX3

Instructions sheet EVJ536N2EX3 -

Instructions sheet EVJ536N2VX3

Instructions sheet EVJ536N2VX3 -

Instructions sheet EVJ536N2VX3XXV

Instructions sheet EVJ536N2VX3XXV

Declaration of conformity to the CE directives

Advantages & Main Features

Per maggiori informazioni su questa gamma consulta la versione desktop del sito.